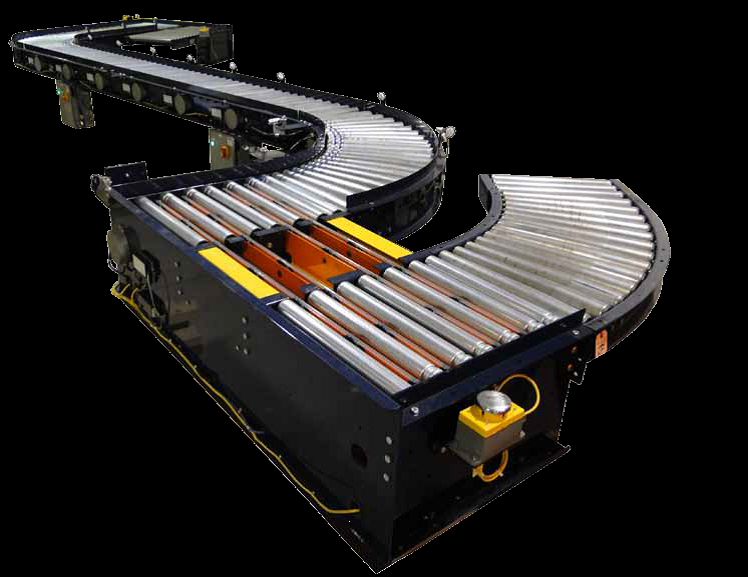

Powered Roller (24v) Conveyor

Some customers do not like high voltage systems and the controls cabinets that they require. 24v powered conveyor systems is the easiest to install because no motor starters and control cabinets are required. Some customers do not like the thought of their conveyor system running even when it is not conveying any products. The 24v powered conveyor only runs the zones where product is present. As a result, our powered conveyer offers a massive reduction in noise, power usage, and wear and tear on the system. 24v powered conveyor has rollers with grooves at one end, a 24v motor in each zone, and urethane O-rings. The 24v motor powers one roller in each zone. That roller is then daisy chained roller to roller with O-rings, to adjacent rollers, within the zone to transfer the conveyable power.

CSI provides 24v powered conveyor when zero pressure accumulation and / or the conveyor operating only when needed, for light loads, is important.

- Quiet… no reducers, high voltage motors, drive chains

- Easy to install… no power drops, controls cabinets,

- Runs when needed

- Zero Pressure Accumulation

- Speeds of 20 – 200 FPM

- 13” to 39” width between the Frames (wider widths available)

If you do not see specifically what you are looking for Contact Us, we are here to assist you. Request a Quote and put our professional personnel to work for you.

We also offer Gravity Conveyor, Powered Belt Conveyor, Belt Driven Live Roller Conveyor, Chain Driven Live Roller Conveyor, Lineshaft Live Roller Conveyor, Accumulation Conveyor, and Sortation Conveyor.