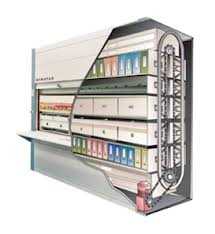

Vertical Carousels

Vertical Carousels spin around an axis just like a carousel does, so the farthest away any product will be is the height of the carousel. Vertical Lift Modules place and pick trays. They are typically much faster than carousels and do not require balanced loading. Most people think that these systems are complex and loaded with software. They do not have to be. The most common Vertical Carousels or Vertical Lift Modules are a single unit about 10 to 12 feet tall and about 6 to 8 feet wide with simple run / stop controls.

Vertical carousels and vertical lift modules are exceptional pieces of equipment. They bring product to the person, saving time, steps, and touches. They can have an exceptional ROI by increasing throughput, reducing required labor, saving space, and increasing security. They can be operated with a simple run / stop or with software that will setup the next pick to an order and display pick location and the quantity to pick. We can assist you in achieving your product / bin to person goals. Keep it simple or let the software do the thinking.

CSI provides carousels and lifts for bringing product to the person, increasing efficiency, security, and utilization of space.

- High capacity

- Durable and Simple

- High Security

- Dense Storage

- Automation that can be kept simple

- Product to Person

If you do not see specifically what you are looking for Contact Us, we are here to assist you. Request a quote and put our professional personnel to work for you.

We also offer Horizontal Carousels, Stretch Wrappers, Strappers, Mezzanines, and Shelving.